The term “graphic printing” began to be used after Johannes Gutenberg’s invention of the printing press around 1450. It grouped all trades related to typographic printing: type usage, printing, binding, finishing, and additional processes applied to printed material. Later, new techniques such as lithography emerged, evolving the sector to what we know today.

"Graphic printing and production can make your campaign extraordinary."

Within graphic production processes, different phases require prior planning. Firstly, you need to be clear about the work requirements. You must know the project’s objectives, what you want to achieve, the target audience for your campaign, the medium and techniques to be used, the quantity of copies to produce, the costs, and the time available. Costs are directly related to the project’s technical characteristics: format, materials, printing system, finishes, quantity of copies, and the time required for execution. Most of the time, all this information will be gathered in a document called “Briefing.” This document is usually prepared by designers, project managers, and clients to ensure all points are perfectly reflected.

After determining the client’s objectives and the briefing, a completely necessary process begins: the design. You can’t start building a house without having made a sketch of what it will look like. Often, we let our creativity fly with the aim of doing something innovative. However, the creative idea has limits found in production. You need a good designer who understands each production process and the importance of coherence between concept and production. They should follow these steps:

1. Create the idea: The client requests a design, and based on what they say, the designer and their team create the idea (designers should know the production limitations the idea might have).

2. Decide the design: Once they have the idea, it must be presented to the client, tweaked, and consider the limitations before moving to the next step, then they mock it up and put the idea into action.

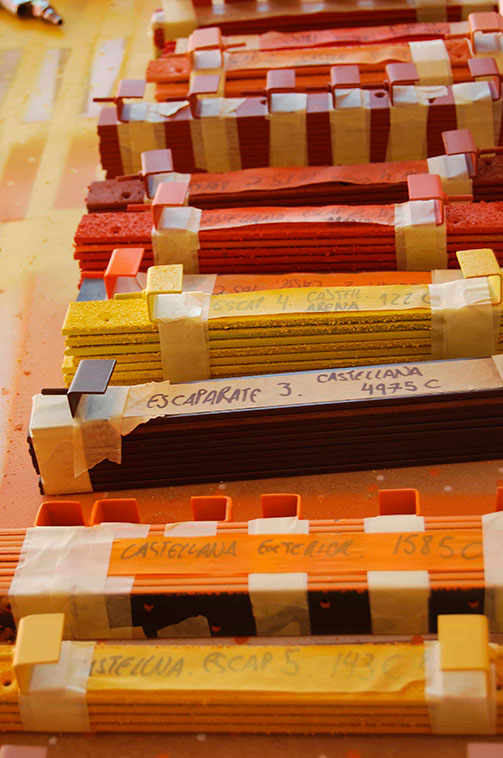

Choice of colors according to Hermès briefing.

"The importance of coherence between concept and production"

For the design development and prepress process, you can work with design programs such as Adobe Illustrator, Photoshop, and InDesign, which provide numerous tools to facilitate the editing process.

With this “prepress” process, we obtain the final design, which will be sent to the printer for production. This design is called “Final Art,” a digital document already prepared for printing, requiring no further modification or intervention. This file must include all the technical specifications we will discuss next:

File dimensions

Ensure the document size is appropriate, according to the medium on which it will be printed and where your campaign will be placed. If you don’t have enough information, it is advisable to first consult the printer about available formats, materials, and prices.

Bleeds

When preparing a document for printing, it should always include an outer margin called “bleed.” The “bleed” is an area outside the workbench where all colour images extend to avoid white parts in your design when printed and cut. The bleed typically ranges between 3mm and 8mm, depending on the type of printing.

Colour

Colour is one of the most important ingredients in your design, as it can be a decisive factor for your project’s success. Colour affects both the visual and emotional aspects of our work. Therefore, when choosing the colours for your campaign, you should be clear about your objectives and know your final customer well.

"Researching the meaning of colours and the impact of each will help you have a higher chance of success in your work."

Colours speak to us, and like words, they convey emotions, desires, goals, aspirations, sensations, and more. Therefore, when choosing the colour palette for your Graphic Design, you must consider the psychological qualities of each colour to develop a design that aligns with the type of product or service you have. Culture, personal experience, and individual mood significantly influence this aspect.

On the technical side, mastering colour usage is crucial to avoid surprises during the Digital Printing phase. Firstly, you need to understand the two basic colour models:

RGB: Additive colours or light colours. These come from the visible light spectrum seen by the human eye, with Red, Green, and Blue as the primary colours, forming all other light colours. This model is used in lighting, monitors, and digital design.

CMYK: Subtractive colours. These are perceived from a surface when light hits it, varying based on the surface qualities. In graphic production, this depends on the ink and material used for printing. The primary subtractive colours are Cyan, Magenta, Yellow, and Black.

This colour system is used in Graphic Design for printing, employing CMYK Colors inks.

Additionally, various printing systems exist based on the type and number of inks used. These can be one-colour, two-colour, four-colour (CMYK), and spot colours. Spot colours are special pre-mixed inks with unique qualities, often referenced by the PANTONE system, widely used by most brands.

Color selection process using the thread counter.

Images

Always check that the images in your design have the correct resolution and colour mode. The resolution is crucial in digital printing to achieve optimal results. High-quality prints should never have less than 300dpi. For medium quality or newspaper/brochure prints, the resolution can be lower, but it should always be as good as possible.

Cut marks and annotations

Cut marks are another crucial element in the prepress design process. “Cut marks” are lines indicating where the printer should cut the document to fit the chosen format. It is usually unnecessary to add these lines manually, as most programs add them when exporting the file, simply by activating the option.

Within the world of graphic arts, there are different types of printing, and with the sector’s advancements, almost any surface can now be printed on. Here is a brief summary of the five most common printing types: relief, permeographic, intaglio, planographic, and non-impact printing. These include traditional printing systems (such as offset, gravure, flexography) and modern (non-impact) digital printing technologies like inkjet or toner.

Planographic printing systems

Planographic printing systems are defined by the fact that the printing and non-printing areas are on the same plane. Gravure is the leading example of these systems. Gravure printing machines use a printing cylinder that has been pre-engraved with microcells capable of retaining and transferring ink to the non-printed surface through the pressure between this cylinder and the material to be printed. This process is widely used in packaging manufacturing, labels, wallpaper, and transfer printing.

Relief printing systems

Relief printing systems, or high relief printing systems, are those where the printing area is raised. This form can be cylindrical or flat, though it is most commonly found in circular and rotary formats. Flexography is the quintessential method in this printing system. It is used for printing on any flexible material and non-porous surfaces. Today, its use remains predominantly in packaging and wrapping.

Permeographic printing systems

Permeographic printing systems have a printing form that is permeable to ink only in the areas to be printed. Serigraphy or screen printing is the standout in this system. Screen printing is an ancient process where ink is directly applied to the material through a stencil or screen.

Embossed printed business cards

Sheet printing with silkscreen.

The stencil has a sealed image that will reproduce the design, allowing ink to pass only through the sealed area while the rest remains unprinted. This system is mainly used in textiles and for merchandising on various industrial objects, including paper, plastic, metal, and three-dimensional surfaces.

Digital printing systems

Digital printing is a direct printing system. Digital printing allows for direct printing on the material without intermediaries through various digital means.

Digital printing on canvas for cinema posters.

This printing system revolutionised the sector due to its immediacy and high quality, making it highly profitable and prevalent in the market. The most common method is inkjet or laser toner. It is used by companies and individuals for small-volume but high-quality prints. It is suitable for launching small promotional campaigns, events, and special offers, large-format printing, and anything that doesn’t require a large print run.

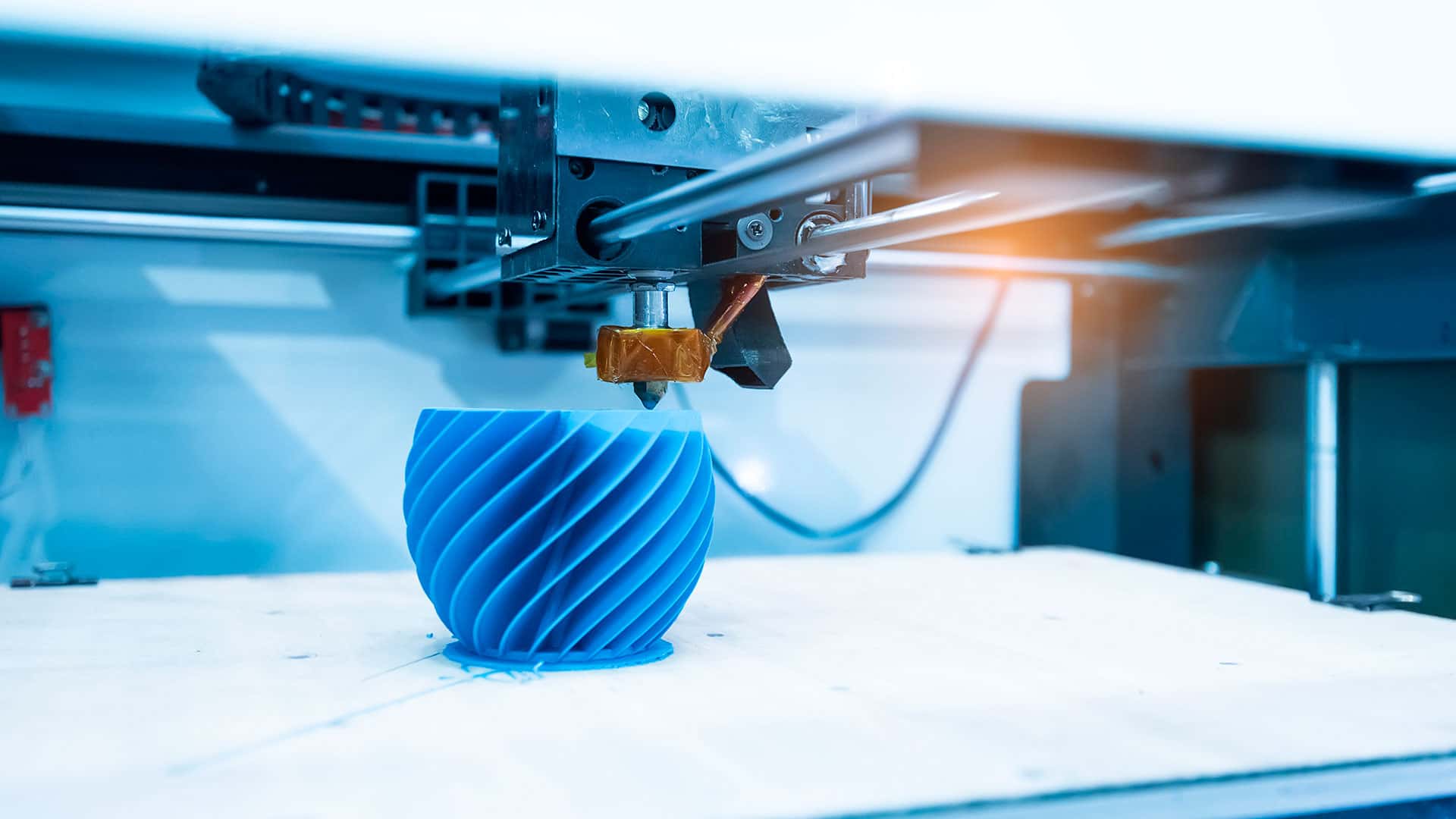

3D Printing systems

Object printed with 3D printing.

3D printing is one of the most innovative manufacturing technologies, capable of printing any three-dimensional object. This technique works by layering successive layers of a specific material from a digital model. There are different technologies and materials within 3D printing, capable of creating and replicating various objects. They have printed prostheses for disabled individuals and even buildings, offering infinite creative freedom. However, it is essential to consider costs, the design’s final use, and the time required.

Depending on the printing process, you may achieve better or worse results. Below are the advantages and disadvantages to consider when choosing a printing system:

Printing posters and billboards

For printing posters and billboards, depending on the quantity to produce, different processes can be chosen. Most of the time, paper is compatible with numerous techniques. For large campaigns, offset printing is recommended due to its cost-effectiveness. If the campaign has fewer units, digital printing is preferable for its high quality and lower cost for short runs.

Printing flyers or brochures

For these projects, offset printing is usually the most recommended due to the large print runs, making it more economical. The paper is compatible with this technique. For exclusive or small promotional projects, digital printing is the best option.

Printing on advertising canvas

Digital printing is highly recommended for this type of work as it accommodates more elastic and rough materials like banners or textiles, offering unmatched quality.

Printing on vinyl

Digital printing is recommended for vinyl due to its excellent finish quality and ease of production, which can reduce costs.

Large format printing

Digital printing is commonly used for large formats because offset machines have more format limitations, and few print shops work with non-standard sizes. The chosen material also influences; if printing on a banner or textile, digital is the way to go.

Large format digital printing for Beefeater advertisement.

Printing on rigid supports

The type of printing machine is crucial for these jobs. Not all machines accept rigid materials, so always consult with the printer first. Digital printing is recommended for its high image reproduction quality and compatibility with such materials. Here are some examples to inspire your future projects.

Digital printing on rigid PVC support for optical shop window decoration

O’neill wood corner print

Printing for packaging and point of sale (POS)

Digital printing.

As you can see, the world of graphic production is vast. I invite you to dive in and research to achieve all the objectives in your design projects.

You may also be interested

open

08:00 AM-18:00 PM Monday – Friday

08:00 AM-18:00 PM Monday – Friday